Test and Tag / Tag and Test – do you need to do it?

Mon April 4th 2022

We often get asked by prospective customers if testing and tagging is something they HAVE to do. We answer your questions.

Test & Tag

Our thermal imaging surveys are unbiased – we aren’t looking for repair work. Our focus is on an independent review of your equipment and your workplace safety.

You’ll get a detailed report of all equipment surveyed within five working days, including location, digital and thermal images, commentary and other details. Click here to download a sample report

LecSafe can do regular equipment surveys and reports at the best time for your business. That way you can catch problems before they need expensive repairs or become dangerous. With our thermal imaging service you can plan ahead for maintenance or replacement, with no down time or costly damage from equipment failure.

You’ll get an easy renewal of your insurance and your cost may go down too. You may even find your insurance company will start asking for these surveys – and with our thermal imaging service reports, you’ll be ready.

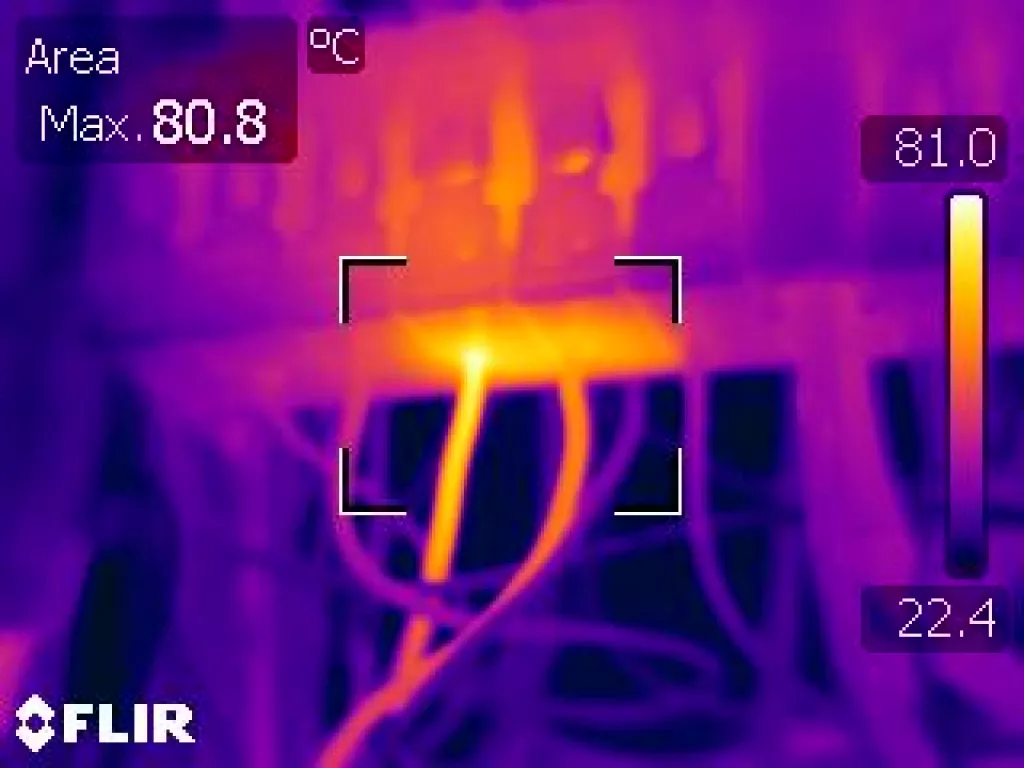

Our thermal imaging service provides a unique look at your electrical cabinets, components and circuit boards. Thermal imaging can pick up issues that are not visible to the naked eye such as hot spots, overloaded circuits, failing components and loose connections. Early detection of these can avoid costly repairs and even prevent catastrophic fires. Get an electrical safety assessment today.

Insurance companies are increasingly requesting thermal surveys of switch boards in commercial and industrial buildings in order to assist in the management of fire risk. Thermal imaging surveys can also form part of your preventative maintenance program enabling the early detection of issues and the ability to plan maintenance or replacement at a planned time that suits rather than when they fail. Failure of electrical components can cause fires or extensive downtime on production equipment which can obviously be incredibly costly.

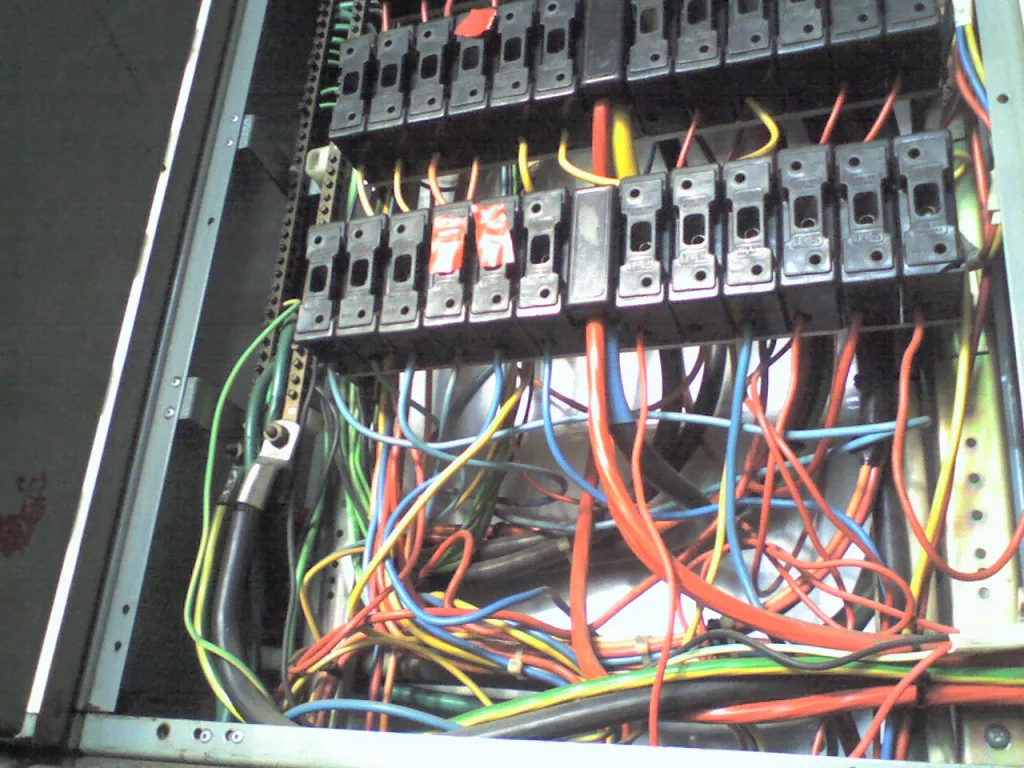

Digital and thermal images of switchboard showing component operating > 80 degrees

Get in touch today to organise a site-visit and quote for your electrical safety programme.

Get startedMon April 4th 2022

We often get asked by prospective customers if testing and tagging is something they HAVE to do. We answer your questions.

Test & TagSun Feb. 13th 2022

We recently completed the electrical testing and tagging to the AS/NZS 3760 standard for Greenpeace NZ.

Case StudiesThu Feb. 10th 2022

Recently we conducted a thermal imaging survey for a global company that relies on heavy machinery to service their client’s equipment.

Case Studies Thermal Imaging